Making Carbon Fiber Composites:

Lighter

Harder

Faster

Stronger

Additive Manufacturing for Advanced Composite Materials

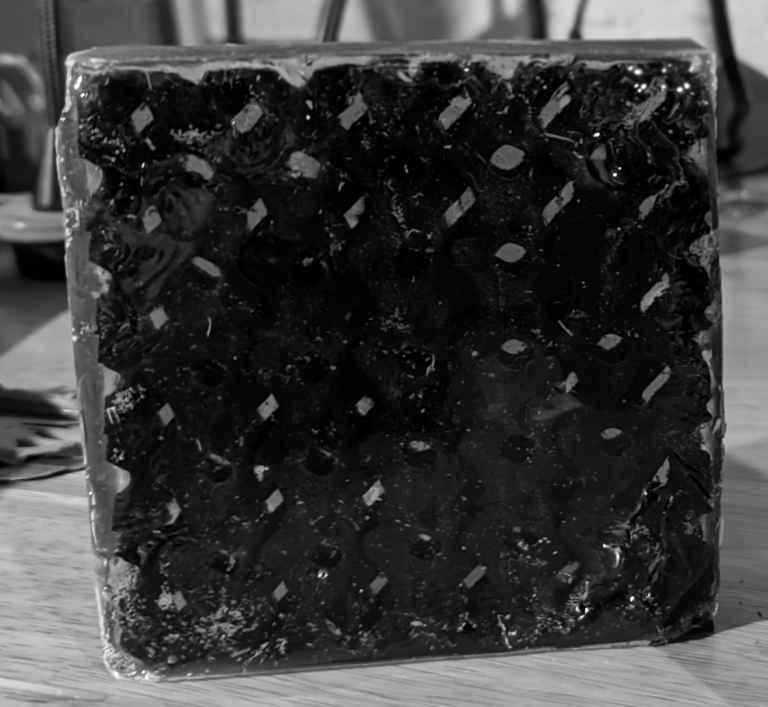

By leveraging topological complexity and huge design freedom, our 3D printed composites will leave traditional composite core designs behind. Traditional carbon fiber 'sandwich' composites are limited to plates and simple forms, while their core materials are completely uniform in their topology - usually a grid or honeycomb hexagonal structure. However, our cores are manufactured on-demand with tailorable topologies, variable densities, and are made of advanced ballistic nylon carbon fiber composites. With additive manufacturing, we can print our carbon fiber structures with far more geometric freedom - leaving simple plate geometries behind.

Carbon Fiber Composites

Carbon fiber is known for its high tensile and compressive strength, high stiffness, and low weight. These properties can be enhanced when utilized as a composite material, and especially when the topology of the composite is. By combining materials across the spectrum for their properties, we can tailor materials to deliver a superior blend of properties. So if you're looking for strong, damage tolerant, and RF shielding - we've got a composite in mind.

Volumetric Freedom

Traditional carbon fiber layup relies on stacking, wrapping, or molding sheets of epoxy and fiber together - requiring complex tooling and manufacturing. With additive manufacturing, our composites can be made with far greater design flexibility and topologically optimized for your applications. Additive enables a high degree of design complexity - enabling carbon fiber structures previously impossible

Topologically Optimized

Additive manufacturing of our composite matrix allows for unparalleled design freedom, spatially variable and tailored performance, and a high degree of strength and weight optimization. We produce composite materials for critical applications where every gram counts - and our carbon fiber structures can minimize weight while maximizing strength. By engineering the topology, we make panels and parts which are are strong and light, but can be tailored to be ductile where need be.

Lay-Up

No More

Carbon fiber composites aren't always known for their low cost - but we aim to change that. By eliminating complex and labor intensive manufacturing steps our carbon fiber panels and matrices will be cheaper pound-to-pound. By additive manufacturing our own molds, forms, and carbon fiber matrices, our carbon fiber reinforced polymer composites (CFRPs) will bring parts to market faster with less risk.

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.